About Us

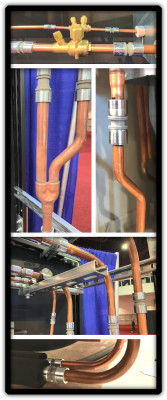

TUFFLOK is the leading manufacturer of mechanically attached fittings for copper pipes. We are dedicated to designing and manufacturing products that are reliable, independently tested for safety, and easy to install. We provide components for a heat-free and stress-free installation of AC&R systems.

TUFFLOK was formed in June 2017 to design, build and sell reliable AC & R connectivity solutions that answer the call for better products with a simple installation method. TUFFLOK is an ISO9001:2015 manufacturer that enables contractors to install reliable copper pipe systems while saving installation time and reducing on-job stress.

We have designed, manufactured, and supplied the AC&R industry with code-listed mechanically attached fittings for seven years. Our philosophy is to provide high-performance, easy-to-install mechanically attached fittings for retrofit, repair, and new installations. We offer ETL-listed lines of mechanically attached fittings available in the industry.

A completely torch-less solution, installations using TUFFLOK components do not require brazing, hot-works permits, system purging, or fire alarm stand-downs. Located in Placentia, California – our connectors are manufactured, tested, quality-checked, and assembled in the USA. Our team comprises mechanical and electrical engineers, compliance and safety engineers, documentation management personnel, order processing, and customer service personnel.

Because we are all under one roof means efficiency in problem-solving and no red tape to get approvals.

We understand that our customers need reliable solutions, quick delivery, and technical support. We work daily to provide reliable products, quality support, and relentless testing of all our mechanically attached fittings.

Our mechanically attached fittings are ETL (Intertek) listed to ensure safe usage and standards compliance. An independent testing organization inspects our facility to ensure manufacturing compliance with applicable codes.

Tuff

What began as a drive to solve a 30-year brazing problem has revolutionized the VRF/VRV (Variable Refrigerant Volume / Variable Refrigerant Flow) industry across the globe. Tufflok is dedicated to making our products reliable and straightforward to install, saving our customers hours of labor expenses.

We continually test our products to maintain impeccable reliability. Testing parameters include tolerance testing on field bent copper tubing (successful up to 4,000 psi on 1-5/8-inch pipe), silicone wraps capability to protect connected joints, insert tolerance analysis to validate the design, and pressure testing to ensure reliable connectivity.

Straightforward Assembly

We understand that skilled brazer professional is difficult to find. To address that shortage, we deliver products that are quick to train, quick to master, and quick to use. TUFFLOK empowers distributors and contractors with connectivity solutions and tools to succeed every time.

Labor Savings

With TUFFLOK’s simple-to-use MAF (Mechanically Attached Fittings) system, you can enjoy labor cost savings of up to 70% and installed cost of up to 50% when compared to welded or brazed fittings.

No Hot Permits Required

Because TUFFLOK uses slide compression fittings as opposed to brazing, contractors that use our system are not required to acquire hot permits. Using our system will save you even more time and money on every job you do with TUFFLOK.